Optimized sorting.

High-quality recycling requires that plastics be sorted according to density. Pla.to systems separate with an improved design – high centrifugal forces with a hydrocyclone generate 22 times the acceleration due to gravity. This ensures exceptional separation precision.

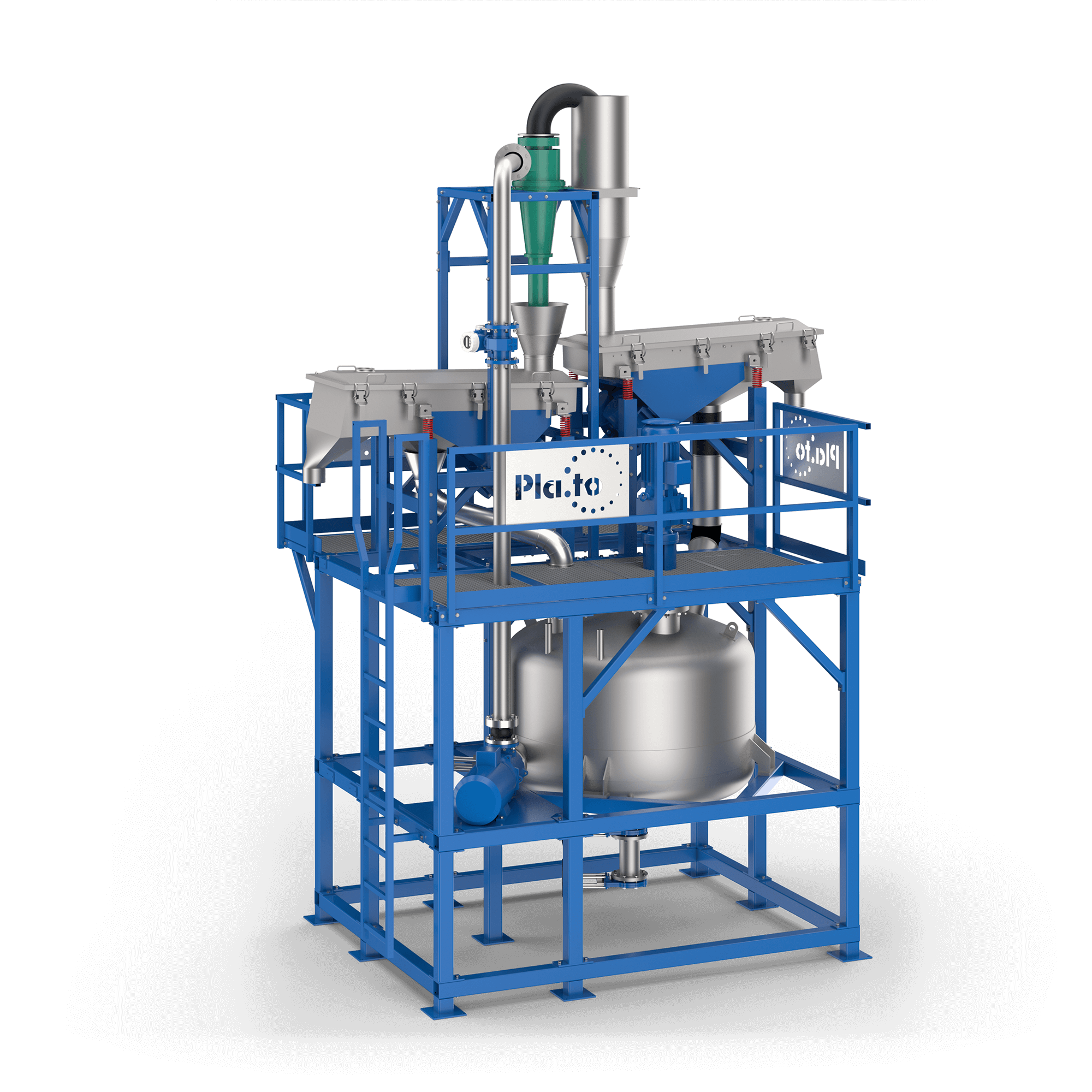

Efficient density separation with improved design

The separation of plastics according to density is an important step in the production of high-quality granules from mixtures. Density separation with water meets this need. Only unmixed plastic is valuable for the processing industry. A specific property profile is a prerequisite for high sales on the market for secondary raw materials.

The separation containers offered on the machine market are usually incorrectly designed. Strong water currents interfere with the density separation in the gravity field. In addition, air bubbles adhere to the plastic, making heavy particles float up. This results in an incorrect sorting. With the hydrocyclone, these problems are eliminated.

The hydrocyclones designed by Pla.to improved work with more than twenty times the acceleration due to gravity and thus achieve a very high degree of separation efficiency. Heavy and light materials leave the container separately.

Our system is distinguished by:

- High selectivity and capacity with a small installation area

- Wear-resistant hydrocyclones made of polyurethane

- Fully automatic continuous and simple operation

- Modern vortex pump for particle sizes up to 15 mm