Engineering

A team effort at Pla.to engineering

- Describe your challenge to us.

- We’ll develop the solution, adapted to your spatial conditions through clever CAD design.

- Paying attention to cost reduction through optimized material flow, we’ll plan your entire process – from shredding to wastewater treatment.

- We provide support from the software planning up to the implementation for a custom-fit sensor and control and we’ll train you employees to use the new systems.

We’ll develop, plan and implement your recycling solution.

Technical Center

Our service for you – test run under production conditions.

In the Pla.to technical center we provide you with a large number of recycling machines, making it possible to carry out decisive production steps from shredding to thermal drying under production conditions.

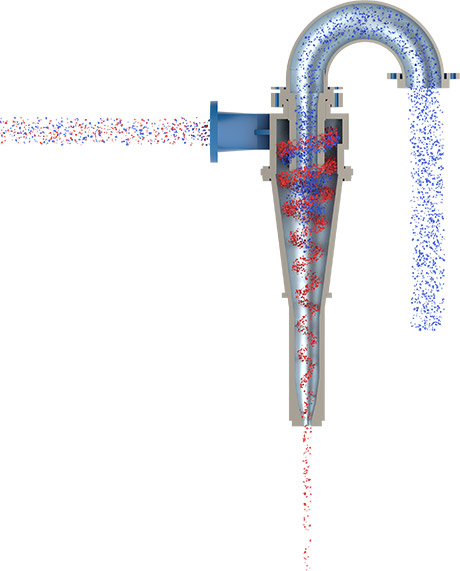

Processes include intensive washing, dry cleaning, hot washing with sodium hydroxide solution, density separation in the hydrocyclone, zig zag air separation, mechanical and thermal drying, sifting and metal separation. Together we will find solutions for even your most difficult challenges.

- Provide a sample of your used plastic.

- We’ll analyze the sample and develop a proposal for the sequence of process steps.

- The starting material gets crushed to an optimal grain size.

- Foreign substances that can damage machines are automatically sorted out.

- The contaminated used plastic is cleaned intensively.

- If necessary, it is then separated according to the type of plastic.

- Finally, the valuable plastic is dried.

The Pla.to technical center – a place for new ideas and inspiration.

Your contact person